Effluent Treatment Plant (ETP)

- Home

- Effluent Treatment Plant (ETP)

Type Of Services

- Bio Gas

- Demineralization Plant

- Commercial RO Plant

- Industrial RO Plant

- RO Desalination Solutions

- Effluent Treatment Plant (ETP)

- Membrane Bio Reactor (MBR)

- Membrane Aerated Biofilm Reactor (MABR)

- Moving Bed Bio Reactor (MBBR)

- Organic waste composter (OWC)

- Commercial RO Plant

- Sequence Batch Reactor (SBR)

- Sewage Treatment Plant (STP)

- Softener Plant

- Ultra Filtration

- Zero Liquid Discharge Treatment (ZLD)

- Solar Plant

Effluent Treatment Plant (ETP)

Effluent Treatment Plants, commonly known as ETPs, are advanced systems designed to treat industrial wastewater, chemical contamination and sewage to ensure that the treated water can be safely discharged into the environment or reused. These plants play a vital role in mitigating the harmful impact of industrial processes on water bodies and the environment. Netsol Water is one of the top-leading effluent treatment plant manufacturer, the brand trusted in the field of wastewater management is a leading wastewater treatment company manufacturing ace machines like Effluent Treatment Plant, Sewage Treatment Plant that not only treats your wastewater but also saves money, saves earth resources. Industries generate vast amounts of wastewater, laden with pollutants and chemicals, which, if left untreated, can cause irreparable harm to our ecosystems. This is where Effluent Treatment Plants (ETPs) come into play as crucial environmental saviors. ETP Plant treats chemicals coming out from Hospitals, Manufacturing Industries, etc. The treated wastewater can further be used in Horticulture, Construction as it functions similarly to the Sewage Treatment Plant.

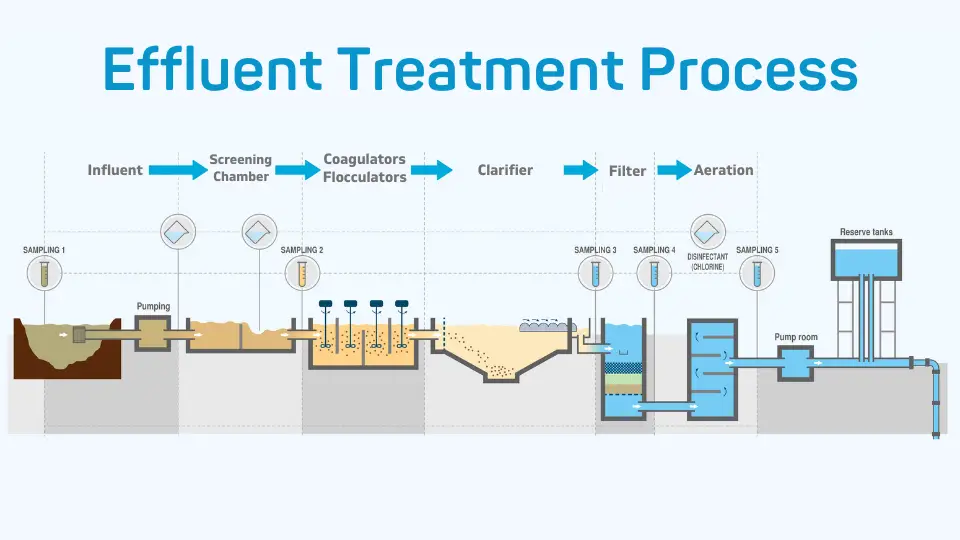

How does an Effluent Treatment Plant work?

Raw effluent enters into the primary filtration chamber where solid waste particles are removed with the help of fine and coarse screens. The next step is the oil & grease trap where the skimmer is used to separate oil from the raw effluent. The raw water then enters into the equalization tank where effluents are cooled down (oxidation) with the help of a blower and maintain equal temperature.

The next step is the neutralization tank, where effluents are mixed with alkali base or acid to neutralize and maintain the ph level and is measured using ph meter. The raw water then moves toward the coagulation tank where coagulant is added such as alum to further remove the layer from the effluent or raw water.

After this process, raw water enters into a settling tank and effluent gets separated from the water and settles down at a lower level of the tank. The effluent removed acts as sludge and can be used as manure in the agriculture industry vice-versa. The last and final stage is the filter stage where filtration is done under the pressure and we get the treated wastewater.

Understanding Effluent Treatment Processes

ETPs employ a range of physical, chemical, and biological processes to clean wastewater effectively. These processes include:

1. Preliminary Treatment

In this initial stage, large debris and solids are removed from the wastewater to prevent damage to downstream treatment equipment.

2. Primary Treatment

During primary treatment, suspended solids and organic matter are settled and removed, reducing the pollutant load in the water.

3. Secondary Treatment

Secondary treatment involves biological processes where microorganisms break down organic pollutants, further purifying the water.

4. Tertiary Treatment

This advanced stage employs additional processes like filtration, chemical treatment, and disinfection to ensure the effluent meets stringent quality standards.

Advantages:

- 1.To clean industry effluent and recycle it for

further use

- 1.To clean industry effluent and recycle it for

- 2.To reduce the usage of fresh water in industries

- 3.To preserve natural environment against pollution

- 4.To meet the standards for emission ofpollutants set by the Government & avoid heavy penalty

- 5.To reduce expenditure on water acquisition

Industries We Serve with ETP Plants

ETP Plant For Paint Shop

ETP Water Treatment Plant For Dairies

ETP Plant For Paper Mills

ETP Plant For Oil Refineries

ETP Treatment Plant For Leather Industry

ETP Plant For Glass Factories

ETP Treatment Plant For Chemical Industry