Membrane Bio Reactor (MBR)

- Home

- Membrane Bio Reactor (MBR)

Type Of Services

- Bio Gas

- Demineralization Plant

- Commercial RO Plant

- Industrial RO Plant

- RO Desalination Solutions

- Effluent Treatment Plant (ETP)

- Membrane Bio Reactor (MBR)

- Membrane Aerated Biofilm Reactor (MABR)

- Moving Bed Bio Reactor (MBBR)

- Organic waste composter (OWC)

- Commercial RO Plant

- Sequence Batch Reactor (SBR)

- Sewage Treatment Plant (STP)

- Softener Plant

- Ultra Filtration

- Zero Liquid Discharge Treatment (ZLD)

- Solar Plant

Membrane Bio Reactor (MBR)

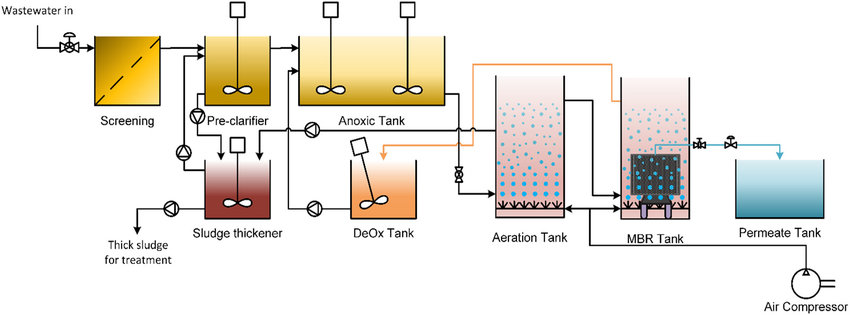

MBR is mainly composed of biological treatment and membrane filtration. In MBR technology, the MLSS is maintained optimum, the amount of bacteria semes before and complete removal of organic matter in relatively smaller. The Membrane has pores size of 0.06 micron wide, makes it so effective that the treated water can be used for flushing application Our MBR technology has experienced best performance in water treatment solutions, fully automatic and reduced manpower, space saving solution, automatic backwash and reduced operating cost. We have expertise in designing of MBR with hassle free and easily, help to reduce maintenance costs, Making waste water treatment more effective, The Filtrate Produced by an MBR can be discharged without Secondary treatment or use for irrigation and other purposes.

How Does MBR Work?

- Biological Treatment: Wastewater enters an aeration tank where microorganisms break down organic matter and nutrients.

- Membrane Filtration: The treated water passes through semi-permeable membranes (Microfiltration or Ultrafiltration), which separate solids, bacteria, and other impurities.

- High-Quality Effluent: The filtered water is free from suspended solids and pathogens, making it suitable for reuse or safe discharge.

- Sludge Management: The concentrated sludge is periodically removed and treated separately.

Advantages:

- 1.Up to 75% Smaller than other Waste Water Treatment System.

- 2.Benefits without UV treatment System.

- 3.Membrane Pore Uniformly Increases flow rate.

Applications

Industries We Serve

MBR Used in Agricultural Industry

MBR Used in Oil & Mining Industry

MBR Used in Hotel Industry

MBR Used in Manufacturing Industry

MBR Used in Residential Societies

MBR Used in Aviation Industry

MBR Used in Automobile Industry