Zero Liquid Discharge Treatment (ZLD)

- Home

- Zero Liquid Discharge Treatment (ZLD)

Type Of Services

- Bio Gas

- Demineralization Plant

- Commercial RO Plant

- Industrial RO Plant

- RO Desalination Solutions

- Effluent Treatment Plant (ETP)

- Membrane Bio Reactor (MBR)

- Membrane Aerated Biofilm Reactor (MABR)

- Moving Bed Bio Reactor (MBBR)

- Organic waste composter (OWC)

- Commercial RO Plant

- Sequence Batch Reactor (SBR)

- Sewage Treatment Plant (STP)

- Softener Plant

- Ultra Filtration

- Zero Liquid Discharge Treatment (ZLD)

- Solar Plant

Zero Liquid Discharge Treatment (ZLD)

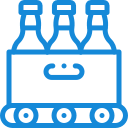

Zero Liquid Discharge (ZLD) is a treatment process that converts wastewater to recycled water and solids, leaving zero discharge at the end of The treatment cycle. The end product of a zero liquid discharge system is a solid residue of precipitate salts that needs to be transferred to a solid waste disposal facility, such as a landfill. The process starts after secondary treatment. ZLD systems include the use of evaporators and brine crystallizers to completely separate dissolved salts from the water. The treatment system combines clarifiers, membrane technologies such as ultra filtration and reverse osmosis, with final stages of brine concentrators, evaporators and crystallizers.

How ZLD Works:

The ZLD process typically involves several key stages:

Pretreatment: Initial removal of large particles, oils, and greases from the wastewater through filtration, sedimentation, or chemical treatment.

Concentration: The pretreated water undergoes processes like reverse osmosis or evaporation to remove dissolved solids, concentrating the effluent.

Evaporation and Crystallization: Further heating of the concentrated wastewater evaporates the remaining water, leaving behind solid residues.

Solid Waste Management: The resultant solid waste is dried and either repurposed or disposed of safely.

THERE ARE SEVERAL ZERO LIQUID DISCHARGE SYSTEMS INCLUDING:

- Combination Thermal Process with zero liquid discharge

- Mechanical and thermal evaporation zero liquid discharge

- Enhanced Membrane and thermal zero liquid discharge

- Evaporation ponds

- Wind-Aided Intensified Evaporation

- De Evaporation

- Salt Solidification and Sequestration.

Advantages:

Environmental Protection: Prevents pollutants from entering natural water bodies, safeguarding aquatic ecosystems and public health.

Water Conservation: Enables industries to recycle and reuse up to 95–99% of their wastewater, significantly reducing freshwater consumption.

Regulatory Compliance: Assists industries in meeting stringent environmental regulations, thereby avoiding potential fines and legal issues.

Resource Recovery: Facilitates the extraction of valuable byproducts from wastewater, offering potential additional revenue streams.

Applications

Industries We Serve with ZLD

Textile Manufacturing

Pharmaceutical and Chemical Processing

Power Generation